Case Study

Video surveillance with scanner locating

at Forwarder Amm

"Now we can process complaints

of partners, recipients and

customers much more efficiently

and clear them faster [...] Thus we

are constantly improving our

processes”

Andreas Wegner

Quality Manager at Forwarder Amm

7 October 2018

Forwarder Amm

Bulky with elegance

Forwarder Amm relies on video surveillance with scanner locating, which also enables the subsequent volume calculation of individual shipments.

Cubage or tonnage: Not only on the weight, but also on the volume of the goods it depends on what basis a freight will be billed. For bulky goods, the actual consignment dimensions are therefore an important information, which is not always stated correctly on the accompanying documents. Thus, the receivers of the general cargo networks lose high revenues every day, which is particularly painful given the already tight margins. The situation is similar in the direct relationship between freight forwarders and shippers.

Volume control at the touch of a button

The Nuremberg based Amm forwarding agency now has quite another solution for this problem, which does not interrupt the loading process and can calculate the volume of a shipment only with the help of a photo. The innovation is called Scale+ and works even when the goods have already left the warehouse. In addition, the volume control is conveniently done on the PC screen, where the contours of the package are traced on a photo using the mouse.

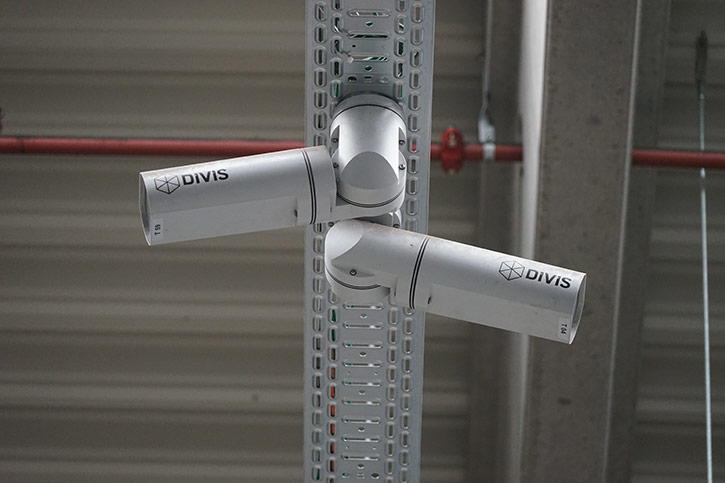

Silently installed

On this basis, Scale+ calculates the volume and visually compares the actual values with the target values stored in the forwarding software. The result can then be exported as a PDF or JPG file for easy proof to the partner forwarder. Scale+ is a Plus+ function (add-on module) of the DIVIS-developed video surveillance solution CargoVIS, which has been in use at Amm since January 2018.

Amm did not only decide for DIVIS due to the sophisticated technology and the unique volume calculation system, but also because of the existing references. "DIVIS has a lot of experience with large projects," says quality manager Andreas Wegner, who is very satisfied with the introduction phase of CargoVIS: "The installation was quick and noiseless." Even subsequent and short-term changes in the order size have been implemented by DIVIS without any problems, he notes.

Integrated locating

The location information is based on the locating system Location+ integrated in CargoVIS, for which each of the approximately 100 scanners was equipped with an UWB tag. It locates each barcode scanner separately and automatically assigns it to the proper camera group in each section of the hall. In a later search with CargoVIS, the complete movement path of each pallet in the cross dock is traceable.

Freed from searching

The CargoLine partner had CargoVIS introduced primarily in order to be able to completely track about 3,500 handled shipments each day. In the hectic day-to-day business between incoming and outgoing goods, it sometimes happens that individual pallets are parked in the wrong shipping zones - and can not be found later for loading. "Given the total hall area of 13,000 square meters and 130 gates, searching for individual pallets without digital support would be far too time-consuming," explains Wegner.

Thanks to DIVIS, the hall employees are now completely freed from searching. If a pallet can not be found in the intended location for loading, it is sufficient to hand over the item number to the colleague in the office by phone. This colleague then uses CargoVIS to detect the image of the pallet at the last reference point plus information on the current location and passes this information on to his colleague.

More safety

In addition to the saved search time and the innovative volume calculation Wegner also mentions a third reason for the introduction of CargoVIS: "Now we can process complaints from partners, recipients and customers much more efficiently and clear complaints faster." A photo of the pallet from the time of loading or unloading creates clear evidence and does not allow discussions about the question of responsibility to even arise. This applies equally to damage as well as wrong loads or loss reports.

To take advantage of this benefit, the image data is stored at Amm for 30 days. "After this deadline, there are no more complaints to be expected, not even in exports," says Wegner, who uses CargoVIS to research around two to five consignments a day. In case he happens to also notice handling errors of the employees, these findings flow anonymously into the next employee training. "This allows us to permanently improve our processes," notes Wegner, who has two inventory scans run during the quieter phases of the day. Thus the experienced logistician creates further reference points, which simplify the later searches and increase the safety significantly.

Deterrent effect

The 23 outdoor cameras, which only the warehouse manager is able to access for privacy reasons, also bring added security. Two of the high-resolution cameras use infrared lighting to send image information that identifies the registration numbers of incoming trucks day and night in all lighting situations. "The main advantage of outdoor cameras lies in their deterrent effect," says Wegner. Damages from vandalism and theft have already only been minor in the past but could be reduced even further by the clever video surveillance.

Conclusion

Amm Spedition has realized a number of advantages with CargoVIS. In addition to significantly reduced search times and accelerated loading, the solution also helps with claims and complaints processing. Last but not least, the volume control with Scale+ supports a fair billing of bulky goods.

BACKGROUND

Forwarder Amm

Amm forwarding is an owner-managed logistics service provider based in Nuremberg and with a branch in Konradsreuth. The medium-sized company has a total of 13,000 square meters of handling space and more than 65,000 square meters of storage space. The company owns more than 160 vehicles and more than 400 swap bodies and semi-trailers. An average of 73,000 shipments with a weight of 63,400 tons are handled each month.

Amm has been a shareholder and partner of the cargo network CargoLine since 1995 and operates CargoLine’s South Hub in Nuremberg. The company, founded in 1966 by Fritz Amm, today employs 450 people, who generate sales of 70 million Euros. The family business is run by Ralf Amm in the second generation.

User video & photos

Andreas Wegner

Quality Manager at Forwarder Amm

photo© Amm