PRESS INFORMATION

Less hardware and more flexibility thanks to tagless BLE locating

Video management for logistics: DIVIS expands solution portfolio with new Bluetooth Low Energy location technology

Bordesholm, August 17. 2021

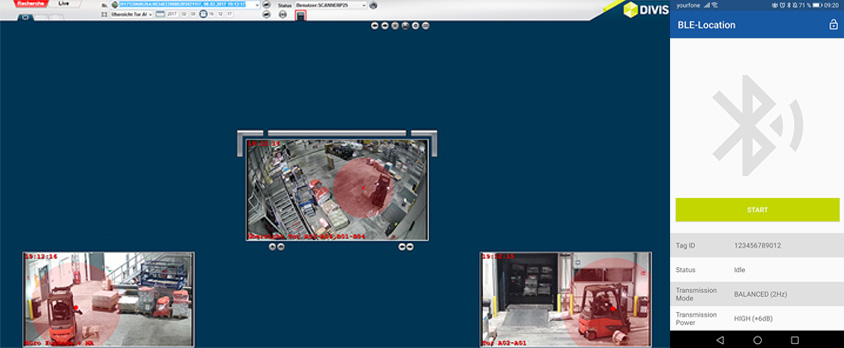

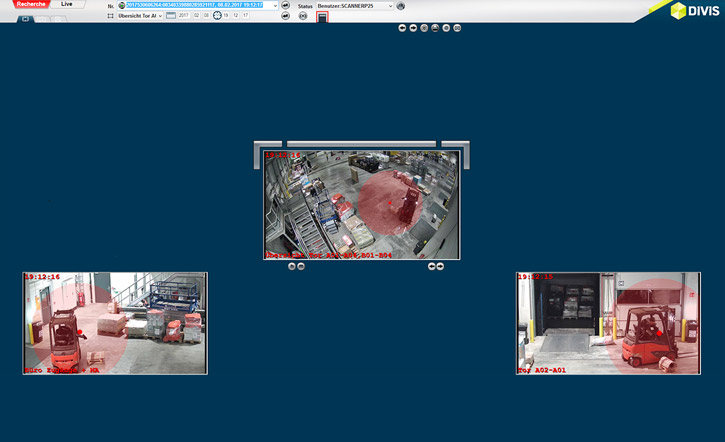

Location+ software interface: visual display of scanner locating with BLE in the logistics hall

Bordesholm, Augsut 17, 2021 +++ Deutsche Industrie Video System GmbH, a technology company specialising in the processes of freight forwarders, CEP and logistics service providers (DIVIS, www.divis.eu), now offers its video management solution CargoVIS with tagless Bluetooth Low Energy (BLE) locating. The CargoVIS software, in combination with camera hardware, can be used to seamlessly track goods in the logistics hall. When a shipment is scanned, the Location+ software module records the current position data. This data is automatically linked to further shipment information - including the images recorded by the cameras. To track the scan stages in image form, employees simply enter the shipment number in CargoVIS. DIVIS now also implements scanner locating tagless via BLE. The specialty of this new indoor positioning technology: no additional hardware is required for the scanning devices. The transmitters for position transmission – small chips (tags) that are attached directly to the device in conventional solutions – are no longer required. Their task is taken over by the BLE app from DIVIS, which is installed on the scanners.

Simple integration and efficient logistics processes

DIVIS developed the app specifically to enable tagless BLE tracking with the CargoVIS software. The app transmits the position data collected via BLE in the system, replacing the tag function. As a result, this locating method eliminates the need for a piece of hardware that could be damaged or rendered unusable by drops. This reduces the maintenance effort. In addition, new scanning devices can also be easily integrated into the locating system at a later date by simply installing the BLE app. Many of the scanner models used in modern halls today meet the technical requirements necessary for this. Bluetooth capability from 4.0 LE and an Android operating system on the mobile terminals are sufficient to use the application. To implement the BLE antenna-receiver system, the logistics hall is equipped once with the corresponding hardware – so-called locators. DIVIS uses robust locators that are suitable for harsh logistics environments due to their reliable dust protection. In addition, they can be updated "over the air" and have a high transmission speed.

Camera and scan data automatically merged

In conjunction with the app and BLE location, the CargoVIS Location+ module enables seamless logistics processes. Goods handling is accelerated because duplicate scans or manual relation entries, such as typing in the gate number, are not required. The software collects video, scan and location data and merges them automatically. Based on this data, missing packages can be quickly located via the user-friendly interface.

Successfully in use at MTG

Location+ has already proven itself in practice at Mannheimer Transport-Gesellschaft Bayer GmbH (MTG). MTG has used it to optimise its logistics processes and make the shipment route through the hall transparent. The logistics service provider initially used the scanner location module with tags. When an overhaul of the location technology became due recently, MTG opted to introduce tagless BLE locating. In the second half of 2021, the company plans to purchase a new generation of scanning equipment and switch to completely tagless equipment as part of that move. The BLE technology is already in use with the existing hardware. Depending on their suitability, the devices either work with the app from DIVIS or are equipped with BLE tags. The site in Mannheim not only benefits from fast and reliable results when searching for shipments. The indoor positioning solution also helps MTG protect worker’s rights. This is possible because with Location+ users can start the video search at exactly the last registered scan time to find missing shipments. This limits the viewing of the video material to the relevant points. In this way, the employees' privacy is protected. In addition, the application offers further options for anonymisation, such as blacking out areas and pixelating people.

Increased efficiency and productivity

Uwe Bayer, Managing Director of Mannheimer Transport-Gesellschaft Bayer GmbH, sums up: "Tagless BLE locating is a flexible, future-proof technology that has increased both our efficiency and productivity. Thanks to the camera images of all scanned shipments, we can clearly allocate goods. The visualisation of the scanning area facilitates orientation. The new locating system has made our processes faster, more transparent and easier to control. Our customers notice that, too."

Hendrik Reger, Managing Director of DIVIS, says: "BLE technology gives our customers maximum flexibility in the use of scanner hardware. Especially when many scanners are in use, for example driver scanners in addition to hall scanners, the tagless BLE system offers advantages. There are no additional costs for transponders, their installation and maintenance, and as a result fewer failures as well. New scanner hardware can also quickly be integrated into the locating system with the BLE app. This saves logistics companies both time and money during implementation and ongoing operations."

Background DIVIS

Deutsche Industrie Video System GmbH (DIVIS) is an owner-managed medium-sized family business with more than 80 employees and over 450 customers in more than 20 European countries. The technology provider based in Bordesholm develops and implements complex video surveillance solutions for freight forwarders, CEP service providers and logistics service providers from a single source.

The CargoVIS system solution was designed for palletised goods consignments in general cargo logistics, while ParcelVIS is used for tracking packages on conveyor-controlled sorting systems and was developed especially for parcel service providers (CEP).

Other products include DamageVIS for the simple documentation of damage to consignments and StoreVIS for the visualisation of picking and returns processes.

Download Press Release